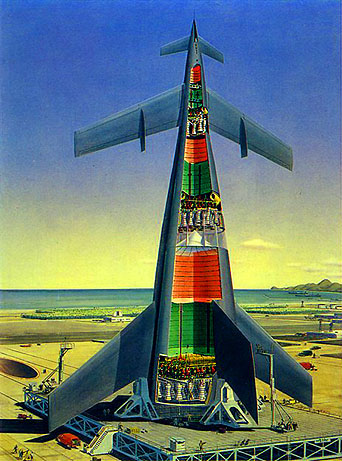

The Von Braun Ferry Rocket jettisons the last stage. The spent stage deploys a ribbon parachute which will attempt to bring the stage to earth gently enough so it can be re-used. Artwork by Chesley Bonestell

Introduction

If you are stuck using pathetically weak chemical rockets and but gotta have big honking slabs of delta-V, the only thing you can do is cower back to the drawing board and try to squeeze more mass-ratio out of your design. The trouble is that a mass ratio of 15 is freaking difficult and 20 is impossible. You will wind up with a ship made of foil and soap bubbles, but still falling short of delta V.

If yer short-sighted boss won't letcha use atomic engines, your only hope is Staging. This is where your ship throws away huge expensive parts of itself when the tanks run dry.

The good news is that the ol' Staging dodge can give you mass ratios of 40 or more. The bad news is you've made your ship into a disintegrating totem pole. And the ship's re-usability just went gurgling down the toilet.

If your spacecraft design needs more delta-V a glance at the Tsiolkovsky rocket equation tells you you have to increase the exhaust velocity or increase the mass ratio. Or both. Since the exhaust velocity depends upon the propulsion system, often the only option is to somehow raise the mass ratio.

Staging is a desperate attempt to increase the rocket's mass ratio in order to increase the delta V to a point where the rocket can perform the desired mission. For a single stage rocket, it is very difficult to get the mass ratio above 15, and it is probably impossible to get it above 20. After all, there is only so much structural mass you can shave off before the force of acceleration will make the struts snap like toothpicks and the tanks pop like balloons.

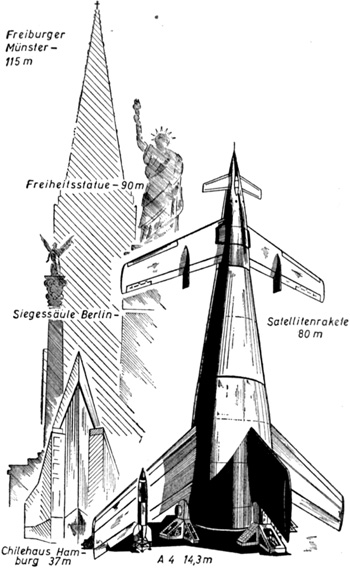

Without staging, there is also a tendency to make huge rockets, due to the constraints of "minimum gauge".

Note also that to get high mass ratios you need BIG rocket ships. That follows because there are minimum weights to many rocket parts. This is known as 'minimum gauge', meaning that you can't make it any thinner or lighter. Combustion chambers have to be rugged. Pipes must be thick enough to hold pressures that don't get smaller just because you're trying to make a small sized rocket.

From The Exploration of the Moon by Sir Arthur C. Clarke (1954) Artwork by R.A. Smith.

Topps "Space Cards" No. 10. (1958)

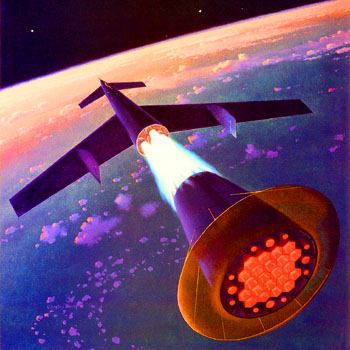

Artwork by William Hutchinson

Pournelle goes on to mention that multi stage rockets make rocket designers subconsciously think of spacecraft as "ammunition" instead of as "aircraft", that is, disposable as opposed to reusable.

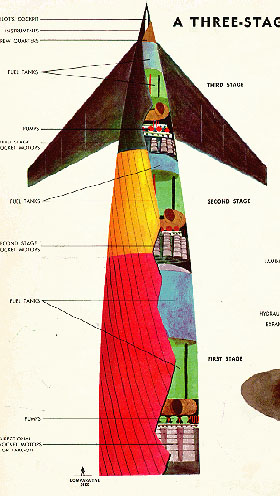

By using staging, the mass ratio of the rocket as a whole can be above 15, even though the mass ratio of each individual stage is below 15. When the current lowest stage has expended all its reaction mass, that stage is discarded. This eliminates the dead weight of that stage's engines, tanks, and structural members. In essence, in a three stage rocket, stage one is a rocket who's payload is another rocket composed of stages two and three.

Back in the old days instead of the term "staging" the common term was "step rockets."

You generally only see staging in extreme circumstances, such as trying to boost a worth-while payload into Terra's orbit with anemic chemical rockets (though in Joan Vinge's THE OUTCASTS OF HEAVEN BELT there was the High Delta V Defense Force, which was an orbit to orbit flotilla of staged vehicles). You do not need staging if you are boosting payloads with atomic rockets. Nor do you need them in deep space, where you have the luxury of using those propulsion systems with high exhaust velocities (and high specific impulses) which regrettably have a thrust to weight ratio below one and thus cannot be used for lift-off.

Which is good because no self respecting Rocketeer wants to ride a disintegrating totem pole if they can possible avoid it. Not to mention the cost if the discarded stages cannot be recovered. Staging also decreases reliability, as you are multiplying the number of propulsion units that can malfunction.

In theory, one could jettison individual tanks and engines as the tanks went dry, but in practice it is more efficient to jettison an entire engine cluster. Having said that, this is the method used by the Space Shuttle with the strap on solid rocket boosters, and by the Otrag. This is called "Parallel Staging".

With staged chemical rockets, the exhaust velocity for the engines of each stage is often different. This is due to complicated optimizations that I will only lightly touch on (since I do not understand it myself). However, I get the impression that most of these optimizations only apply to lift-off, not to deep space missions.

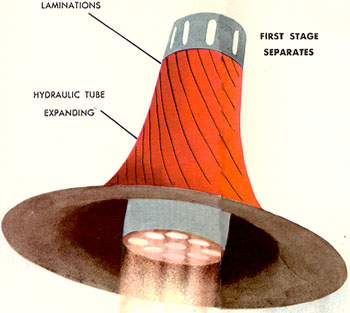

Artwork by Earl Oliver Hurst. The stage body is formed from parallel metal strips, creating the diagonal lines.

Artwork by Earl Oliver Hurst. After being jettisoned, the strips hydraulically fan out to create a rigid parachute, so the stage has a fighting chance of hitting the ground gently enough to be re-used.

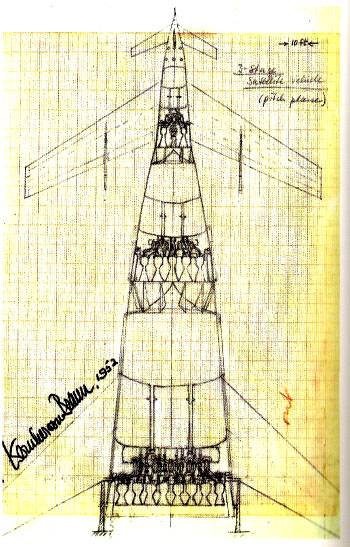

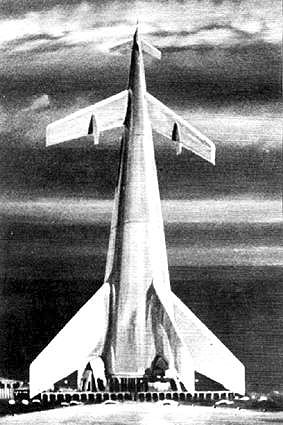

Von Braun Ferry Rocket. Click for larger image

Von Braun Ferry Rocket

They were one segment of the Grand Harmony's high delta-vee defense force, specially designed, specially equipped with a fuel-to-mass ratio of one thousand to one. Although Raoul Nakamore ranked in the highest echelons of the Harmony navy, he had always maintained that their existence was a pointless waste of desperately needed resources; and for that reason he had never been on board one of these ships before. But now the starship had changed his mind; as it could change the very future.

He sank heavily into the padded seat as the ship's liquid-fuel boosters ignited and thrust grew to a steady two gravities, more than slightly painful on his Belter's frame. He checked the chronometer on the panel. Thrust would continue for thirteen hundred seconds, boosting them to sixteen kilometers per second... and in that time, expend seven thousand tons of fuel, the outer stages of the three ships themselves, and of seven drones. And still it would take them over two megaseconds to reach Lansing -- and their quarry might not even be there.

Mass Ratio

With staging, to figure the effective mass ratio of the entire rocket, you take the individual mass ratios of each stage and multiply them. Now you know why staging is so popular with rocket scientists, despite the many draw backs.

When figuring the delta V contribution of a given stage, you use the standard delta V equation, but when figuring the mass ratio you use the total mass of the rocket after discarding the previous stage to plug into the equation.

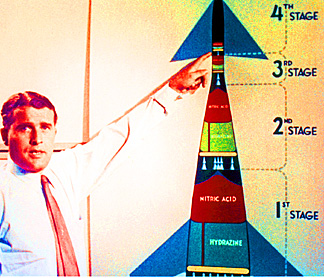

Say that Tom Swift's Star Spear has a mass of 100 tons and has three stages. Each stage has a chemical engine with an exhaust velocity of 4,500 m/s (gotta love Tom Swift's amazing solar-powered Kicker). Recall that the equation for mass ratio is:

R = (Mpt / Me) + 1

where

- R = mass ratio (dimensionless number)

- Mpt = mass of propellant (kg)

- Me = mass of rocket with empty propellant tanks (kg)

Say that 80% of the mass of the Star Spear is the fuel of the first stage (obviously since the ship is 100 tons this would make Mpt = 80 tons), and 10% is the dry mass of the first stage, and 10 % is the remaining stages of the rocket (which makes Me = 10 + 10 = 20 tons).

Plugging this into the equation makes the mass ratio of stage one of the Star Spear:

- R = (Mpt / Me) + 1

- R = (80 / 20) + 1

- R = 4 + 1

- R = 5

This means that the delta V contributed by stage one is:

- Δv = Ve * ln[R]

- Δv = 4,500 * ln[5]

- Δv = 4,500 * 1.61

- Δv = 7250 m/s

Now say that the other two subsequently smaller stages are similar to the first (which will probably never be the actual case). The delta V of all three stages will be

- Δv = 3 * 4,500 * ln[5]

- Δv = 3 * 4,500 * 1.61

- Δv = 3 * 7250

- Δv = 3 * 7250

- Δv = 21,800 m/s

Remember the effective mass ratio is found by multiplying together the mass ratios of each stage. So the Star Spear should have the same effective mass ratio as a single stage rocket with a mass ratio of 5 * 5 * 5 = 125! Does this check out? Let's see:

- R = e(Δv/Ve)

- R = e(21,800/4,500)

- R = e(4.84)

- R = 127

Well, 127 is close enough to 125 for government work. The idea is the important thing.

Of course, since only 10% of each stage is payload, the actual payload of the final stage is 10% * 10% * 10% = 0.1%, and 0.1% of 100 tons is 100 * 0.001 = 0.1 metric ton or 100 kilograms.

Delta-V

Artwork by Virgil Finlay

The total delta V of the multi-stage rocket is obviously the sum of the delta V contributions of each of the stages. Since delta V is Ve * ln[R], a three stage rocket's total delta V would be:

Δv = (Ve1 * ln[R1]) + (Ve2 * ln[R2]) + (Ve3 * ln[R3])

where

- Δv = ship's total deltaV capability (m/s)

- Ve1 = exhaust velocity of propulsion system in stage 1 (m/s)

- Ve2 = exhaust velocity of propulsion system in stage 2 (m/s)

- Ve3 = exhaust velocity of propulsion system in stage 3 (m/s)

- R1 = mass ratio of propellant in stage 1 to (dry mass of stage 1 plus total mass of stage 2 and 3)

- R2 = mass ratio of propellant in stage 2 to (dry mass of stage 2 plus total mass of 3)

- R3 = mass ratio of propellant in stage 3 to dry mass of stage 3

The Galileo rocketry club has assembled a three stage sounding rocket. Stage one has a dry mass of 40 kilograms and has 50 kilograms propellant with a specific impulse of 230 seconds (exhaust velocity of 230 * 9.81 = 2260 m/s). Stage two has a dry mass of 22 kilograms and 15 kilograms of propellant with a specific impulse of 250 seconds (exhaust velocity of 2450 m/s). And stage three has a dry mass of 12 kilograms and 9 kilograms of propellant, also with a specific impulse of 250 seconds (exhaust velocity of 2450 m/s). The payload is 10 kilograms. What is the total delta V?

Recall that mass ratio is:

R = (Mpt / Me) + 1

Therefore, the mass ratios of the three stages will be:

- R1= (50 / (40+22+15+12+9+10)) + 1

- R1= (50 / 108) + 1

- R1= 1.46

- R2= (15 / (22+12+9+10)) + 1

- R2= (15 / 53) + 1

- R2= 1.28

- R3= (9 / (12+10)) + 1

- R3= (9 / 22) + 1

- R3= 1.41

The total mass ratio will be:

- Δv = (Ve1 * ln[R1]) + (Ve2 * ln[R2]) + (Ve3 * ln[R3])

- Δv = (2260 * ln[1.46]) + (2450 * ln[1.28]) + (2450 * ln[1.41])

- Δv = (2260 * 0.378) + (2450 * 0.247) + (2450 * 0.344)

- Δv = 854 + 605 + 843

- Δv = 2302 m/s

Optimization

Artwork by Virgil Finlay

Your next question is how does one determine the optimum mass ratios of each stage. I was afraid you'd ask that. It's a bit complicated. You are given the Δv requirements for the mission Δvm, and the mass of the actual mission payload (the weather satellite, the ICBM, the Apollo command and lunar module, the interplanetary warship, the orbital fighter, whatever).

To optimize a multi-stage rocket, go through the following steps, taken from the SMAD. You'll quickly discover why they call it "rocket science."

Choose the number of stages

This will be called nstage. Choose the minimum number of stages that is practical. Choose different values for nstage and compare the marginal differences.

Choose specific impulse for each stage

The primary choice is the highest specific impulse, and if this is for lift-off you'll need a thrust to weight ratio above one.

But sometimes it is advantageous to use a propellant that has a higher density (which generally means a lower specific impulse). Sometimes if a higher density propellant is used for the lower stages, it will give you a better inert-mass fraction, which gives you a lighter first stage. But only sometimes. In other cases it may give you a lighter first stage but a heavier total vehicle mass. You will have to try and see.

Choose the inert-mass fraction for each stage

A stage's "inert mass" is the total mass of the stage minus the mass of the propellant and the mass of the payload. Inert mass is used because while we know the payload mass, we generally have no way of knowing the structural mass.

To find the "inert mass fraction", divide the inert mass by the total mass of the stage.

In existing chemical rocket designs, the inert-mass fraction of a given stage tends to be between 0.08 and 0.7.

Allocate a fraction of delta-V to each stage

The goal is to divide up the Δv contributions in such a way as to minimize the vehicle mass. But the only way to discover this is by trying different combinations (see step 6 below).

In the special case where each stage has the same inert-mass fractions and the same specific impulse, they will also have the same Δv fraction. The fraction will be 1 / nstage. For example, if there are four stages, each stage will contribute 1/4 = 0.25 = 25% of the total Δv.

Size the stages and the vehicle

Start with the final (uppermost) stage and work backwards to the first stage. The payload of the uppermost stage is the actual mission payload. The payload for each lower stage includes all the previous upper stages plus the actual mission payload.

So, starting with the uppermost final stage, the payload mass is equal to the actual mission payload. The specific impulse (Isp) for this stage comes from step 2. The inert-mass fraction (finert) for this stage comes from step 3. And the Δv fraction (fΔv) for this stage comes from step 4.

Using those values, we can calculate the propellant mass, the inert mass, and the initial mass of that stage.

To calculate the propellant mass: specific Impulse gives us the Exhaust Velocity:

Ve = g0 * Isp

Δv fraction and mission Δv gives us the stage Δv:

Δvs = fΔv * Δvm

Δvs and Exhaust Velocity gives us the Mass Ratio:

R = e(Δvs/Ve)

Payload mass, mass ratio, and inert mass fraction gives us the Mass of the Propellant:

Mpt = (Mpl * (R-1) * (1 - finert)) / (1 - (finert * R))where:

- Ve = Exhaust velocity (m/s)

- Δvm = total mission Δv

- fΔv = Δv fraction for this stage

- Δvs = Δv for this stage

- g0 = Acceleration due to gravity at Earth's surface = 9.81 (m/s2)

- Isp = Specific impulse (s)

- ex = the inverse of the Ln() function, called "exp(x)" in spreadsheets

- finert = inert-mass fraction

- Mpl = mass of "payload" (kg)

- Mpt = mass of propellant (kg)

To calculate the inert mass:

Minert = (finert / (1 - finert)) * Mpt

Finally, to calculate the initial mass of the stage:

M = Mpl + Mpt + Minert

For the next lower, and all subsequently lower stages, use the value of the previous stage's initial mass M in the place of the payload mass Mpl, use the new stage's values for Δv fraction, specific impulse, and inert-mass fractions. Re-calculate all the equations with the new values.

Keep doing this until you have finished all the stages. The initial mass M of the last stage is the vehicle's initial mass. The goal is to get the vehicle's initial mass to be as low as possible.

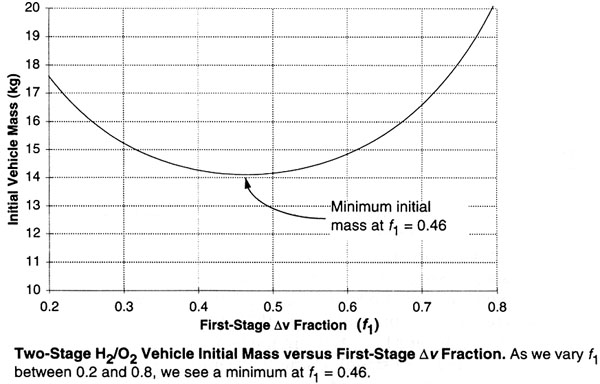

Minimize the vehicle mass by optimizing the delta-V fraction alloted to each stage

Graph from Space Mission Analysis and Design (1999).

The Δv fractions of each of the stages must be varied in order to determine the combination that minimizes the vehicle's initial mass. This generally is done with an "iterative process," i.e., a computer program, a grad student, or unlucky you has to repeatedly run various combinations of Δv fractions through steps 4 and 5 until the minimum initial mass is discovered.

With a two stage rocket, it is, well, I won't say "easy" but it is a lot easier than a three or more stage rocket. Obviously with a two stage rocket, once you've decided on a value for the Δv fraction of stage one, you have automatically determined stage two's Δv fraction (i.e., it is 1.0 - fΔv1).

So you set a range of values for the Δv fraction of stage one (say, from 0.2 to 0.8) and step through it at convenient intervals (say, increment by 0.1 each step). Subtract from 1.0 to figure the fraction for stage two. Send these through the battery of equations above and plot them on a graph like this:

By inspecting the graph, you can identify the minimum value for initial vehicle mass, and the associated Δv fractions. Your optimization is complete.

Performing this for three or more stages is a major pain in the gluteus maximus.

We need to vary two Δvs over some range to find a minimum. For a three stage system, we repeat the above graphing technique for a range of fΔv2 values, choosing the minimum fΔv1 value for each fΔv2 (remember fΔv3 = 1.0 - fΔv1 - fΔv2). We can then plot the initial vehicle mass (each point being minimized for fΔv1) and choose the fΔv2 with the minimum initial mass value.